- Posted on

- Bhanu Pratap

Unplanned plant downtime puts challenges across industries like healthcare, manufacturing, and energy, leading to a loss of about 10% of production time and increased operational costs (Clyk). To address such situations, the SAP Plant Maintenance process comes to the rescue by providing a structured approach for tracking, executing, and scheduling the plant maintenance tasks.

In this blog, we will explore features and components of SAP plant maintenance, how SAP PM can help optimise business maintenance processes and the role of technology in the SAP maintenance system. In addition, you will also know how the right SAP PM consultancy from PatternBots can help in improving the maintenance procedures of your business.

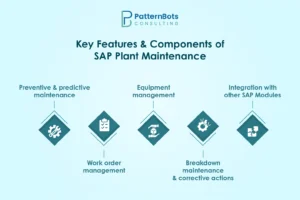

Key features and components of SAP Plant Maintenance

With SAP plant maintenance scheduling, organisations can easily reduce unplanned downtime, increase asset life cycles, and minimise overall operational disruptions. All such processes are enabled with the following features and components of SAP plant management:

1. Preventive and predictive maintenance

SAP PM schedules servicing and inspections at regular intervals, ensuring preventive maintenance. It also uses data analytics and condition-monitoring techniques to predict equipment failures. This way, you can use SAP for maintenance planning and predictive maintenance.

2. Work order management

With SAP PM, businesses can easily create, track, and manage all the work orders. By maintaining document issues, scheduling repairs, allocating resources, and tracking the completion of work, the SAP maintenance system ensures proper work order management.

3. Equipment management

The SAP plant maintenance module helps manage technical objects like machines, equipment, and functional locations. It helps businesses store data related to equipment specifications, performance metrics, and maintenance history so that asset tracking and management become easier for managers.

4. Breakdown maintenance and corrective actions

SAP maintenance management ensures quick responses in situations of equipment failure with its breakdown maintenance feature. Businesses can log such incidents with the help of SAP PM, analyse the root causes, and implement corrective actions so that normal operations can be resumed efficiently.

5. Integration with other SAP Modules

The SAP plant maintenance module easily integrates with different types of SAP modules to create a linked and connected enterprise system. These are the modules that stay connected entirely with SAP PM:

- SAP MM (material management): This module manages the availability of spare parts and maintenance materials.

- SAP SD (sales and distribution): This module manages the maintenance service contracts.

- SAP PP (production and planning): This module aligns all the maintenance schedules with production timelines.

With the integration of all these modules, coordination between different departments improves, refining the overall efficiency.

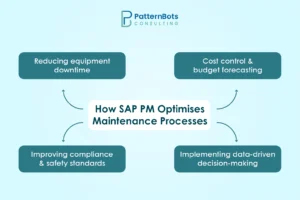

How SAP PM optimises maintenance processes

With SAP PM, tracking maintenance history, automating repairs, and facilitating every maintenance request become easy for businesses. SAP PM can promptly plan and manage the maintenance processes by:

1. Reducing equipment downtime

Businesses can track real-time equipment performance by using SAP maintenance management. It ensures prompt scheduling of maintenance activities so that issues are addressed as early as possible. This reduces unexpected failures, increases the availability of equipment, and also boosts productivity.

2. Improving compliance and safety standards

Industries like manufacturing, energy, and healthcare have to comply with strict regulatory standards. SAP quality management systems help maintain such compliance by ensuring that safety checks are accurately performed, regulatory guidelines are rightly followed, and maintenance activities are properly documented.

3. Cost control and budget forecasting

With SAP order management, you can track the costs and use features like budget forecasting to optimise the maintenance expenses of your business. This involves the analysis of historical data and the prediction of future maintenance needs, which help prevent unnecessary expenditures.

4. Implementing data-driven decision-making

SAP PM comes with analytical tools and reporting features, which help businesses make informed decisions by using real-time data. The insights from maintenance reports help the management in identifying trends, improving overall planning, and implementing updated strategies for maximising operational efficiency.

Role of technology in SAP Maintenance

With the help of advanced technologies, the SAP maintenance process is also improving. These are some technologies that are playing a major role in SAP PM:

1. IoT and AI:

By integrating the Internet of Things and Artificial Intelligence, SAP PM has revolutionised maintenance management in organisations.

- IoT-enabled sensors are used to regularly monitor equipment and send real-time information to the SAP PM.

- AI-driven predictive analytics are helping businesses detect upcoming failures and take timely measures before breakdowns.

2. Mobile solutions:

SAP PM mobile solutions also help in real-time monitoring by providing access to updated work orders to the maintenance team and reporting every real-time issue. This way, the responsiveness of the team can be improved, and delays in maintenance operations can also be minimised.

3. Cloud-based SAP PM:

Cloud-based SAP PM solutions are providing greater flexibility and accessibility to businesses. Due to this, companies are now able to access maintenance data from any place, allowing proper collaboration among the teams and improved operations.

How PatternBots can help with SAP PM consultancy

If you need SAP for the maintenance planning of your business, PatternBots can help you with their experienced SAP consultants. As the leading SAP consultancy, we specialise in SAP PM implementation and support. Our years of experience in providing SAP solutions help businesses in optimising their maintenance process with the latest SAP technologies.

With these tailored solutions, you can integrate with third-party systems for smooth data exchange, make custom reporting for better decision-making & analysis, and automate the maintenance workflows for improved efficiency of your operations. With our experienced team of SAP consultants, PatternBots has helped multiple businesses streamline their maintenance processes with SAP PM.

Conclusion

Investing in SAP PM is a strategic decision for businesses, as they can build reliable asset management. It helps companies reduce costs, improve operational efficiency, and comply with industry standards. With SAP PM consultancy from PatternBots, you can ensure a longer equipment lifespan, reduce downtime, and allocate resources in a much better way. If you are looking for an optimised SAP PM for your business, PatternBots will be the right choice for your consulting needs.

Frequently Asked Questions

SAP PM is a module in SAP ERP that helps manage and maintain business processes, ensuring excellent asset performance. It helps minimise downtime, reduce maintenance costs, achieve compliance, and streamline maintenance planning with automation and integration with other SAP modules.

The main components of SAP PM are: Maintenance Notifications, Maintenance Orders, Preventive Maintenance, Equipment Management, Work Clearance, and Maintenance Planning.

By automating preventive maintenance, scheduling work orders, allocating resources, and integrating with inventory and procurement, SAP PM manages unplanned downtime and provides real-time tracking for maintenance planning and execution.

SAP Order Management generates, tracks, and executes maintenance work orders, and by allocating resources, it integrates with SAP MM for material availability, tracking maintenance costs, and streamlining the approvals.

SAP consultants help in system implementation, customisation, and integration. By suggesting the better usage of SAP PM, they help with the process efficiency of the business, ensure regulatory compliances are met, and support continuous improvements for plant maintenance management.