- Posted on

- Bhanu Pratap

At the start of this week, we spoke with a manufacturing team that couldn’t align production plans with orders. They told us, “We have material requirements planning, spreadsheets, and daily meetings, but we still can’t avoid missed deadlines.” It sounded all too familiar.

And the numbers back it up. According to Gartner (2024), only 32% of planners use new planning software once it’s implemented, leaving advanced tools to gather dust. With that kind of adoption gap, ERP-native scheduling tools never deliver. That’s why just having production planning and scheduling software like SAP PP/DS is not enough, but businesses should also know how to use it in a better way.

So this blog will help you with a detailed guide on what SAP PP/DS in S/4HANA is, its functionalities, benefits, and challenges. In addition, we will also explain how PatternBots can help you with the setup and adoption of the SAP PP/DS module.

What is SAP PP/DS?

SAP PP/DS (Production Planning and Detailed Scheduling) is an advanced component of SAP S/4HANA that allows businesses to create comprehensive and capacity-aware production plans. With its advanced features, businesses can easily plan and execute the production processes, like generating production plans, reducing lead times, increasing product throughput, and minimising costs of stock across the enterprise.

With the SAP PP/DS module, businesses can also classify materials to determine their requirement for advanced manufacturing, which helps in effective planning of resource schedules and identifying order dates and times.

To get a better idea of what functionalities your business can get by implementing SAP advanced planning and scheduling systems, it is important to understand the features of SAP PP/DS. Let’s explore them in detail.

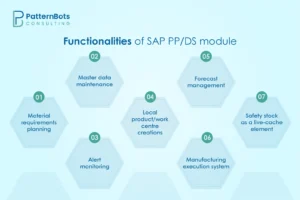

Functionalities of SAP PP/DS module

The SAP PP/DS module comes with different components and features that make high-level material planning and detailed production execution much easier for businesses. Some of these are:

1. Master data maintenance

By maintaining the master data in SAP production planning, businesses can ensure that the systems have current and accurate information about the production process and all the mapping functions are aligned well with the modelling blueprint before implementing planning workflows.

2. Manufacturing execution system

A manufacturing execution system is software that helps organisations with monitoring, controlling, tracking, and documentation of the production lifecycle. When MES is combined with PP/DS in SAP, businesses can increase the accuracy & visibility of the production process and respond quickly to the changes occurring in production operations.

3. Safety stock as a live-cache element

Safety stock is the inventory which is kept as a reserve in case of material shortages or unexpected surges in demand. The safety stock can also be configured with PP/DS in SAP to ensure that sufficient stock is available to fulfil customer requirements. You can add that as a live cache, using the “SAP_PP_019 – Create Safety Stock in SAP Live Cache” heuristic.

4. Material requirements planning

Material requirements planning is a tool of SAP PP/DS that calculates important material requirements for production on the basis of established production plans. For better production planning, relevant MRP (material requirement planning) procedures should be used so that production delays can be avoided.

5. Local product/work centre creations

Local products and work centres are used when businesses work in different locations and with different resources. These products and centres are created in SAP advanced planning and scheduling systems by feeding information like production parameters, material requirements, and lead times. With this, production processes can be managed in alignment with production goals.

6. Forecast management

Forecast management helps in anticipating future trends so that businesses can make informed decisions related to inventory, scheduling, and production quantity. It helps in PP/DS planning by allowing more precise forecasting of material requirements.

7. Alert monitoring

While doing PP/DS planning, alert monitoring is used to establish rules and regulations to trigger alerts in case of changes in metric values. PP/DS monitoring tools are designed for those alerts so that businesses can keep track of alerts related to orders and operations. For accurate alert monitoring, users must define an alert profile that sets the rules and thresholds for the detection of material availability issues affecting scheduling.

Once the right features are in place, SAP PP/DS can deliver several advantages across the production process. Let’s explore them.

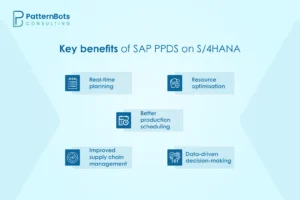

Key benefits of SAP PPDS on S/4HANA

SAP PP/DS, as a production planning and scheduling software, helps businesses handle and manage complex manufacturing procedures. When businesses use PP/DS in SAP, they get real-time updates of everything happening around the production floor. Here are some major advantages businesses get while using SAP production planning and detailed scheduling:

1. Real-time planning

When businesses use SAP production planning and detailed scheduling, they can plan the manufacturing processes in real time. The memory computing feature of SAP production planning helps companies to assess potential disruptions, optimise production plans, and simulate different production scenarios.

2. Resource optimisation

With SAP advanced planning and scheduling systems, businesses can use available resources in a much optimised way, be it machinery, raw materials, or human resources. By managing setup times, handling resource availability, and setting production priorities, the SAP production planning module ensures that every resource is allocated in an efficient way.

3. Better production scheduling

SAP production planning systems use advanced algorithms to optimise the production sequences on the basis of factors like order priority, material flow, and availability of materials. This way, businesses can ensure a smoother process as the bottlenecks are reduced and capacity overloads are also avoided with the alignment of production plans with inventory levels.

4. Improved supply chain management

The SAP production planning module integrates seamlessly with supply chain processes and smoothens up the procurement, inventory management and sales activities. With such integration, production planning gets aligned with the goals like optimal stock level maintenance, excess inventory reduction, and improved delivery timelines.

5. Data-driven decision-making

The SAP production planning system is supported by embedded analytics, which offers meaningful insights of real-time production performance metrics. With such analytical capacity, businesses can identify future trends and ensure data-driven decisions. This improves the visibility of the production process, and any issue arising can be addressed before it escalates.

To fully realise these benefits, businesses must first address certain challenges that can arise during adoption and system integration. Let‘s explore what those challenges are.

Launching PP/DS applications from Fiori launchpad

Like any sophisticated solution, the adoption of SAP PP/DS comes with its own set of challenges. Here are some common challenges that businesses might experience:

1. Lack of integration with upstream and downstream systems

One of the biggest challenges is integrating SAP advanced planning and scheduling software with other systems like ERP, MES (Manufacturing Execution Systems), and supply chain platforms. Without proper integration, your planning process may end up relying on outdated or incomplete data.

2. Insufficient data quality

The SAP advanced planning and scheduling software relies heavily on master data such as material master, BOMs (Bill of Materials), routings, and work centre capacities. If this data is incomplete or inaccurate, the system will produce flawed schedules.

3. Complexity of configuration

Configuring the production planning process in SAP can be complex, especially if your production processes involve multiple plants, product variants, or specialised constraints. Over-customisation can also lead to maintenance difficulties down the line.

4. Change management and user adoption

Adopting a sophisticated tool like SAP PP/DS often requires a shift in how planners and schedulers work. Without proper change management, users may revert to manual planning methods or resist using the system entirely.

5. Performance and system tuning

As the volume of data grows, some organisations face performance issues with long run times for heuristics, optimisation, or planning runs. This can delay decision-making and affect responsiveness.

With the right approach, these challenges can be turned into opportunities. Here is how PatternBots can support your SAP PP/DS adoption.

How can PatternBots help in overcoming the challenges of SAP PP/DS?

If you are looking to streamline your SAP PP/DS implementation and enable smarter production planning without complexity, PatternBots is here to support you. Our expert SAP consultants will help you assess, configure, and implement the right production planning and scheduling approach based on your business needs.

With over 15 years of experience in SAP solutions, our team can assist you with data readiness assessments, system integration planning, performance tuning, and end-to-end PP/DS adoption strategies. Work with us to simplify your production planning processes, enhance user adoption, and build a scheduling solution that is scalable, reliable, and aligned with your operational goals.

Conclusion

SAP PP/DS helps businesses manage complex manufacturing procedures and bring greater clarity to production planning and scheduling. By choosing the right implementation approach and addressing key challenges early, you can streamline planning workflows, reduce manual work, and improve production efficiency. If you are planning to adopt or optimise SAP PP/DS, PatternBots can help you design and deploy a production planning solution that delivers measurable results.

Frequently Asked Questions

SAP PP/DS is an advanced component of SAP S/4HANA that helps businesses plan and schedule manufacturing processes. It enables capacity-aware planning, optimises production sequences, and supports real-time decision-making to improve efficiency and minimise lead times.

The core components include master data maintenance, material requirements planning, detailed scheduling, forecast management, alert monitoring, and integration with Manufacturing Execution Systems. These components work together to enable accurate production planning and scheduling across complex manufacturing environments.

PP/DS integrates with MES to provide real-time visibility of shop floor operations. By synchronising production orders, material movements, and resource availability, this integration helps businesses monitor, control, and adjust production processes in response to changing operational conditions.

PP/DS supports detailed scheduling, finite capacity planning, material requirements planning, and scenario-based production simulation. It helps businesses create optimised and realistic production plans that account for material availability, resource constraints, and priority rules.

Forecast management helps businesses anticipate future demand trends for better planning. Forecast consumption aligns these forecasts with actual sales orders, helping businesses manage inventory levels effectively while ensuring that production is driven by the most current demand signals.

PP/DS provides configurable alert monitoring tools that trigger alerts based on predefined thresholds. These alerts notify planners of issues such as material shortages, scheduling conflicts, or capacity overloads, enabling quick action to prevent disruptions in the production process.

To deploy PP/DS, businesses must run SAP S/4HANA and ensure the availability of key components like Live Cache, CIF integration, and relevant master data structures. Additionally, proper system sizing and performance tuning are recommended for optimal planning run times.