- Posted on

- Bhanu Pratap

At the start of this week, we had a conversation with a distribution company that was struggling to make sense of its inventory data. Their team said, “We have reports, dashboards, and cycle counts, but we still can’t trust our stock numbers.” It sounded like a familiar problem we always come across.

This got us talking about how common inventory blind spots really are. According to a recent report from Firework (2024), 43% of small to midsize businesses either don’t track inventory at all or use manual methods like spreadsheets. With numbers like that, it is no wonder delays, stockouts, and write-offs are still such a big problem. Businesses don’t know how SAP Inventory Management can help them reduce waste, maximise overall operational efficiency, and make the most of their technological investment in inventory management.

So, we decided to pull together this guide to explain how inventory management actually works inside SAP S/4HANA, how it can help you move past those blind spots, and how your team can make better use of the tools you already have. Let’s take a look.

What is SAP Inventory Management?

SAP Inventory Management is a core module within the SAP Enterprise Resource Planning suite, designed to manage the overall flow of inventory and products throughout the supply chain of an organisation. The SAP inventory system manages the processes of ordering, managing, storing, and distributing the products, right from procurement to distribution. With SAP inventory software, you can also integrate inventory management with other subsystems of your business, like sales, shipping, and accounting.

Now that we have covered the foundation, let us move into how SAP Inventory Management supports real-world operations through its main features.

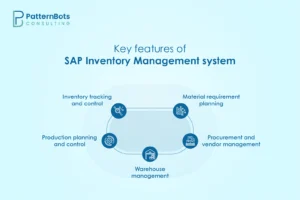

Key features of SAP Inventory Management system

The SAP inventory management system offers different features to ease off the processes of inventory control and simplify warehouse operations. These features can be categorised into the following key areas:

1. Inventory tracking and control

The SAP inventory system offers real-time visibility of the inventory levels across every location, ensuring vigilant tracking of stock movements. With SAP Inventory Management, you can manage complete material master data, which can help you get detailed information related to descriptions, classifications, and specifications of every stock item for better control.

2. Material requirement planning

The SAP inventory software uses demand forecasting techniques to anticipate future demands for every material so that businesses can ensure timely procurement and plan production accordingly. To facilitate more accurate material requirements planning, SAP Inventory Management manages the Bills of Material (BOM) structure, detailing the main components required for each product.

3. Warehouse management

The SAP inventory software can easily integrate with a warehouse management system to streamline operations and tasks like picking, packing, shipping, goods receipt, and putaway. The SAP Inventory Management system also maintains information about storage locations in the warehouse for efficient stock placement and easy retrieval.

4. Procurement and vendor management

With the SAP stock management system, businesses can manage complete vendor information, as it helps in managing different data, like contact information, delivery schedules, and payment terms. By streamlining the tasks of purchase order creation, vendor communication, and approvals, SAP IM helps automate procurement workflows.

5. Production planning and control

SAP Inventory Management helps businesses with production planning activities, such as scheduling production orders, monitoring production progress, and allocating resources. It also integrates with the floor control systems of the factories to manage the production activities, optimise the production process, and ease the resource utilisation processes.

To use these features effectively, SAP provides direct access shortcuts. Let us take a look at the most commonly used transaction codes in SAP Inventory Management.

Important transaction codes (T-codes) in SAP Inventory Management system

SAP Inventory Management software can be used easily when you know all the important transaction codes. These are the shortcut keys that offer direct access to transaction information within the inventory system. Here are a few of the important transaction codes that can help you manage SAP IM more efficiently:

- MB1A: Used for withdrawing goods from inventory.

- MM60: Displays a list of materials in the system.

- MIGO: Handles all types of goods movements, such as receipts and issues.

- MB1C: Used to post incoming goods into inventory.

- MM02: Allows changes or updates to existing material master data.

- MBST: Cancels previously posted material documents.

Once you understand the system and how to navigate it, the next question is what outcomes you can expect. Let us explore the benefits of using SAP IM in your business.

Benefits of SAP Inventory Management solutions

SAP Inventory Management software offers a range of solutions to manage the materials and inventory throughout the supply chain. With accurate inventory counts and valuations, SAP IM offers different benefits, like

1. Reduced inventory costs

SAP Inventory Management solutions help organisations reduce inventory costs by controlling stockouts, reducing overstocks, and optimising inventory levels. With features like material requirements planning, just-in-time inventory management, and ABC analysis, SAP IM helps in reducing the overall inventory cost.

2. Enhanced customer service

With the SAP stock management system, businesses can improve their customer service by ensuring that customers get the right products delivered to them as per their demands. SAP IM comes with features like order fulfilment tracking and available-to-promise functionality, which helps in getting real-time visibility of inventory levels. This helps businesses make accurate promises to customers about product availability and deliveries.

3. Improved productivity

When businesses use SAP software for inventory management, they can easily automate tasks and simplify the warehouse processes. The features like warehouse management systems help in automating the picking, shipping, and packing processes, while barcoding and RFID features can help automate data capture and inventory tracking processes.

4. Increased supply chain visibility

With SAP software for inventory management, businesses get real-time visibility of their supply chain. It comes with a dashboard that offers real-time updates on different supply chain metrics, helping businesses make informed decisions on supply chain performance and problems. It also offers supply chain analytics, which can improve the supply chain efficiency of the businesses.

5. Reduced risks and improved compliance

SAP Inventory Management software can be used to generate and see regulatory compliance reports. It helps businesses stay compliant with all the regulations that are relevant to warehouse operations. SAP IM also helps in identifying and assessing supply chain risks, which helps businesses with timely mitigation.

How can PatternBots help you with SAP Inventory Management consultation?

If you want to optimise inventory workflows and improve visibility across your supply chain, PatternBots is here to support you. Our expert SAP consultants will help you evaluate your current setup, configure the right features, and implement SAP Inventory Management based on your business needs.

With over 15 years of experience in SAP solutions, our consultants can guide you through planning, deployment, and ongoing support. Work with us to simplify your inventory processes, reduce operational errors, and drive better results with SAP.

Conclusion

SAP Inventory Management helps businesses reduce waste, improve inventory accuracy, and increase supply chain efficiency. With real-time stock tracking and automation, it becomes easier to manage warehouse operations and support better decision-making. If your current inventory process is holding you back, this might be the right time to look at SAP Inventory Management and get the expert support you need to do it right.

Frequently Asked Questions

SAP Inventory Management is a core module within the SAP Enterprise Resource Planning system that helps companies manage the flow of materials and products across the supply chain. It tracks inventory right from procurement through storage and distribution, offering full visibility into stock levels, material movements, and warehouse activities. With SAP Inventory Management, businesses can control goods receipts, goods issues, stock transfers, and internal movements while keeping accurate records of all inventory transactions.

Traditional inventory systems rely heavily on manual tracking and disconnected tools. On the other hand, SAP Inventory Management is a centralised platform with real-time data visibility. It automates critical tasks like goods movement, material requirement planning, and warehouse operations, reducing the chances of human error. SAP Inventory Management also connects well with other business processes like procurement, production, and finance, helping companies avoid stock discrepancies, reduce waste, and make faster, data-driven decisions.

The SAP Inventory Management system comes with a wide range of features to manage and optimise inventory operations. Some of the main features include:

- Inventory tracking and control, which provides real-time visibility of stock levels and material movements.

- Material requirement planning, which uses demand forecasting to ensure timely procurement and accurate production schedules.

- Warehouse management, which streamlines storage location tracking, order fulfilment, picking, and putaway tasks.

- Procurement and vendor management, which helps manage supplier data, purchase orders, and approvals.

Production planning and control, which assists with scheduling, resource allocation, and monitoring of shop floor activities.

SAP Inventory Management helps businesses streamline supply chain operations by providing accurate, real-time data and automating key processes. It reduces the risk of stockouts and overstocks, improves warehouse workflows, and enhances order fulfilment accuracy. By integrating features like available-to-promise, order tracking, and material valuation, SAP Inventory Management supports better planning, faster decision-making, and increased visibility across the supply chain.

In SAP Inventory Management, T-codes, or transaction codes, are shortcut commands used to quickly access specific inventory functions. Each T-code is a unique combination of letters and numbers that directs users to the right section of the system. Here are a few important T-codes used in inventory management:

- MB1A: Used for withdrawing goods from inventory.

- MM60: Displays a list of materials in the system.

- MIGO: Handles all types of goods movements, such as receipts and issues.

- MB1C: Used to post incoming goods into inventory.

- MM02: Allows changes or updates to existing material master data.

- MBST: Cancels previously posted material documents.

These T-codes help users complete inventory tasks more efficiently without having to navigate through multiple menus.